Reading time : 4 minutes

Last update : January, 2026

In the ever-evolving world of optical engineering, the debate between glass and plastic optics continues to shape the choices of designers and manufacturers. While glass has long been the material of choice in high-precision applications, advances in polymer technologies have closed the performance gap significantly. Today, plastic optics offer a compelling alternative, one that combines versatility, cost-efficiency, and innovation.

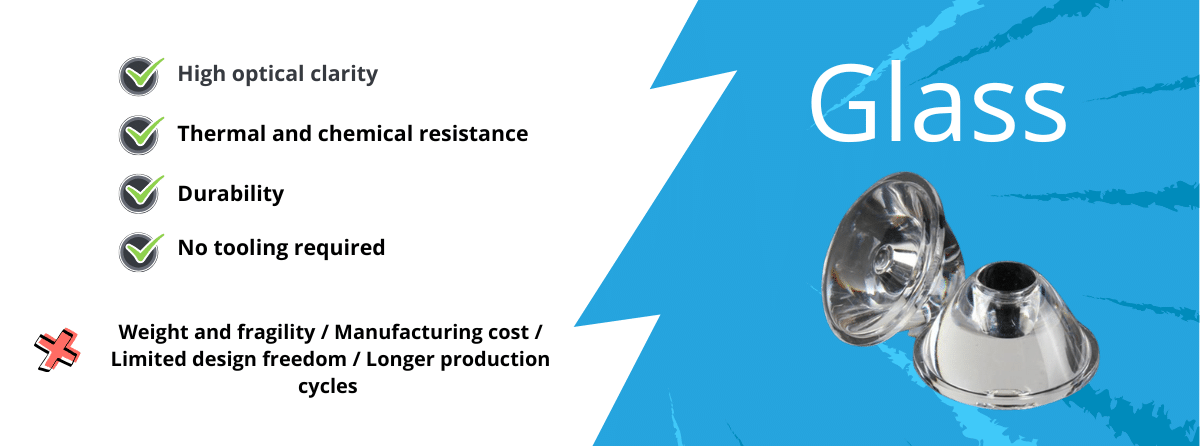

Glass Optics: Precision at a price

- Glass optics have traditionally been favored for their exceptional optical clarity, thermal stability, and scratch resistance. They are particularly well-suited for high-power laser systems, harsh environmental conditions, and applications demanding extremely low optical distortion.

- Advantages of plastic optics:

- High optical clarity: Glass maintains high transmission across a broad range of wavelengths, including UV and IR.

- Thermal and chemical resistance: Ideal for extreme temperature environments and exposure to aggressive solvents.

- Durability: More resistant to scratches and long-term deformation.

- No tooling required: Prototyping is fast and accessible, with no upfront investment in molds.

However, these advantages come with significant drawbacks:

- Weight and fragility: Glass lenses are heavier and more prone to breakage.

- Manufacturing cost: Each lens is individually ground and polished, which drives up the per-unit cost, especially for volumes over 1,000 units.

- Limited design freedom: Aspheric and freeform surfaces require complex and expensive grinding setups.

- Longer production cycles: Grinding and polishing inherently limit speed and scalability.

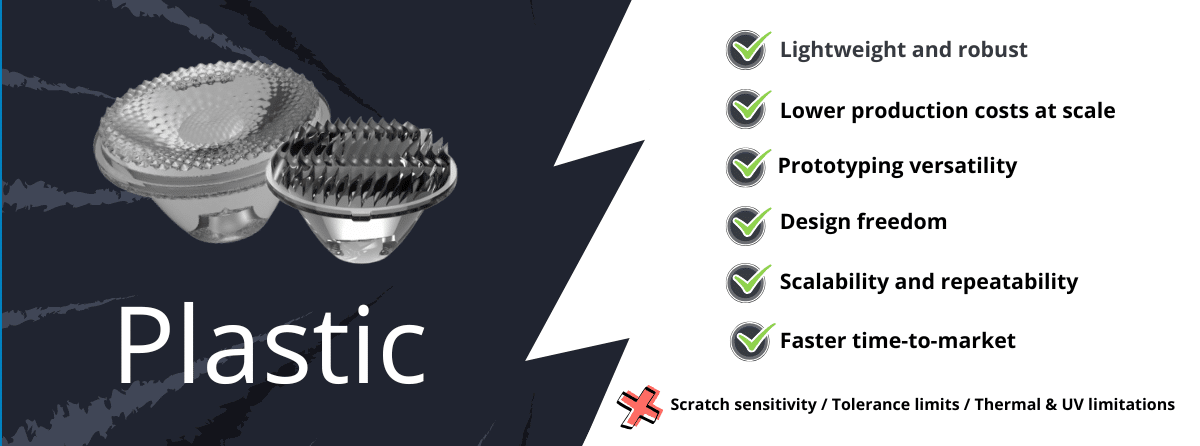

Plastic Optics: Performance meets flexibility

Plastic, or polymer optics, have seen remarkable development in recent years, particularly with the emergence of high-performance materials and sophisticated molding techniques. Optical-grade plastics such as PMMA, PC, and COP/COC offer properties that rival traditional glass in many scenarios.

Advantages of plastic optics:

Lightweight and robust: Plastics are significantly lighter than glass, reducing the overall weight of optical systems, a key factor in several industries applications.

- Lower production costs at scale: Though injection molding requires an initial tooling investment (typically €5,000–€35,000), the per-part cost in high volumes drops below €2.

- Prototyping versatility: Plastic lenses can be prototyped without molds using diamond turning, CNC milling, and ultra-precision polishing, enabling quick, functional one-offs.

- Design freedom: Plastics allow complex geometries (e.g., aspheric, freeform, Fresnel) and integrated alignment or mounting features, all in a single molding cycle.

- Scalability and repeatability: Once tooling is in place, optics can be produced at scale with consistent quality.

- Faster time-to-market: Rapid prototyping techniques and scalable molding allow for swift transition from concept to production.

Drawbacks:

- Scratch sensitivity: Plastic surfaces are generally softer, though protective coatings can mitigate this.

- Thermal and UV limitations: Some materials are more susceptible to temperature changes or UV degradation, requiring careful selection based on application.

- Tolerance limits: While sufficient for most imaging and lighting systems, plastics do not yet match glass in ultra-precise optical tolerances under all conditions.

Gaggione: Mastering the art of plastic optics

At Gaggione, we understand that the future of optics lies in smart, scalable, and sustainable solutions. With decades of experience in plastic optics, we have honed the expertise and infrastructure needed to produce high-precision components for the most demanding industries.

Our advanced injection molding facilities, combined with in-house design, diamond turning, rapid prototyping, and metrology capabilities, allow us to deliver custom optical solutions with unparalleled quality and repeatability. Whether you need complex aspheric lenses or compact light guides, Gaggione is uniquely positioned to turn your concepts into reality, with the flexibility, speed, and cost-efficiency only plastic optics can offer.

Conclusion

While glass optics continue to serve niche, high-performance needs, plastic optics have emerged as the smart choice for modern optical system design, thanks to their cost-efficiency, lightweight nature, and design flexibility.

With advanced manufacturing techniques like diamond turning, high-precision injection molding, and rapid prototyping, plastics are no longer a compromise, they are a competitive edge. They enable faster development cycles, lower production costs, and more innovative geometries, such as aspheric and freeform surfaces, all while supporting high-volume scalability.

By choosing plastic optics, you gain:

- Agility in design and iteration

- Scalability for mass production

- Integration of optical and mechanical features

- Speed-to-market with industrial-grade repeatability